Категории

Languages

Търсене

Фирма WOKU

Product filters for fluidized bed systems

Product filters for fluidized bed systems

Product filters are developed in close collaboration with our customers. With our almost 40 years of experience our careful selection of materials and our professional processing we supply filter elements in OEM quality.

The special fabrics we use were developed specifically for this kind of application and have demonstrated their suitability over decades of use.

These fabrics are the same as the ones supplied by the fluidized bed system OEM, so no changes are necessary. For special applications and process optimizations we also carry a wide range of further developed fabrics.

The different sizes and designs are specially fabricated to fit the various equipment types perfectly.

All of the synthetic components used which come in contact with food or pharmaceutical products are completely harmless, and certified according to FDA CFR Title 21, Part 177 and/or EC No. 1935/2004, EU 10/2011.

Filter bags for fluidized bed systems

Filter bags for fluidized bed systems

Filter bags for fluidized bed systems are fabricated by using our special processing technologies.

With their optimum fit and the use of special filter media and accessory parts they achieve the best process reliability.

We can also fabricate additional filter elements according to your requirements using the same high quality fabrics.

- Exhaust air filters for high-shear mixers

- Outlet sleeves for product outlets

- Connection sleeves

- Covers for product containers

Mesh screens made of stainless steel

Of course we can also supply you with mesh screens made of high quality stainless steel fabric for use as bottom screens in product containers. Please ask us specifically about this.

Fabrication & filter fabric

Fabrication

High quality materials, precision workmanship and the highest standards of quality lead to an optimal and reliable product. Our specialists have been designing and fabricating product filters and supplying them to customers around the world since 1979.

Filter fabric

The filter fabric is the most important component in a product filter. It performs the particle separation and product retention so it is decisive for product gain within the process.

The thread polymers are FDA-compliant according to CFR Title 21, Part 177 and/ or comply with EC Regulation No. 1935/2004, (EU) No. 10/2011 regarding materials and objects made of plastics which are intended for coming in contact with foods.

Using either stainless steel or carbon threads, all electrostatically conductive (antistatic) fabrics are permanently antistatic for the highest process safety.

Seam sealing

In order to optimize the product gain it is useful to seal the seams of the filter element if extremely high separating fabrics are used. This prevent from product loss through the sewing holes.

Professional repair service

Used filters which have small holes don’t necessarily have to be replaced by new ones. Often the filter elements can be repaired and used again.

The product filters are completely inspected in our plant, the damages expertly assessed and if possible they are then repaired so that the filter can be reliably used again.

Filter cartridges for fluidized bed systems and & vacuum conveyors

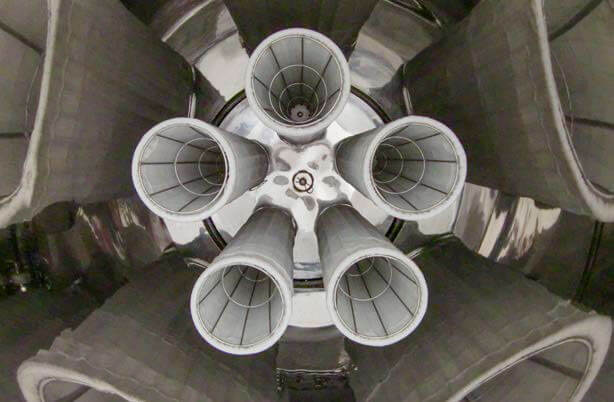

Filter cartridges for fluidized bed systems

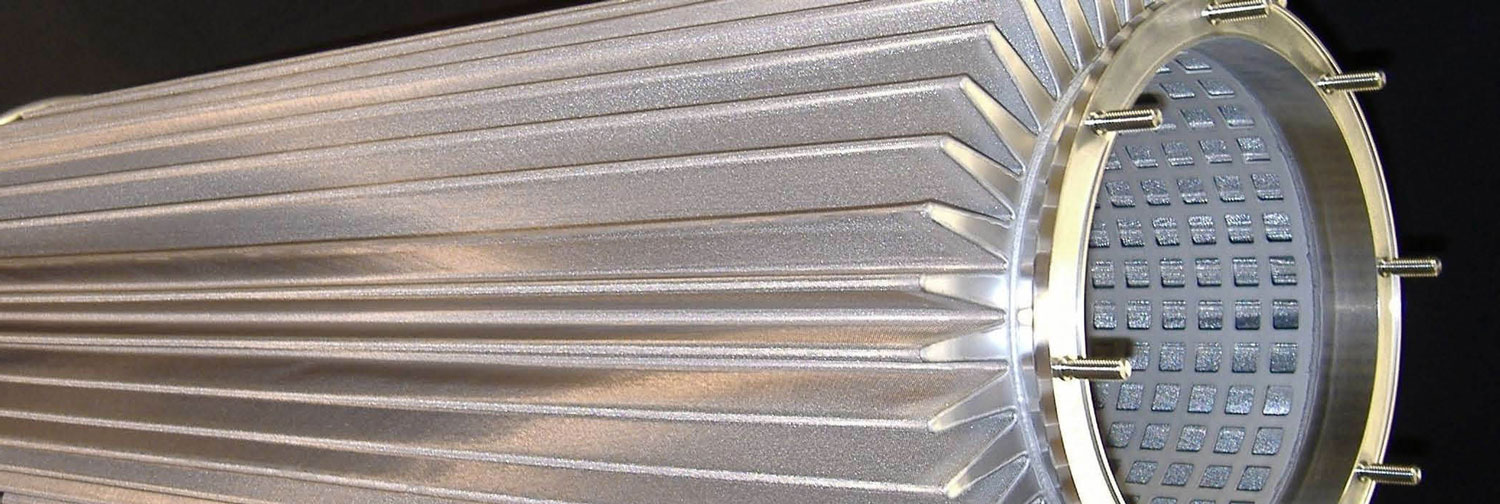

Filter cartridges for fluidized bed systems are produced from special stainless steel fabric laminates, also including a CIP-capable version. Pleated (starshaped) and cylindrical (smooth) versions are available, depending on use-case and customer needs.

Other non-CIP-capable filter cartridges which are in use in fluidized bed systems are mainly made of special synthetic filter materials.

All the synthetic components used which come in contact with food or pharmaceutical products are completely harmless, and certified according to FDA CFR Title 21, Part 177 and/or EC No. 1935/2004, EU 10/2011.

Filter cartridges for vacuum conveyors

To filter finest dust particles out of the vacuum flow high quality filter cartridges are necessary.

All filter cartridges for vacuum conveyors are completely harmless and certified according to FDA CFR Title 21, Part 177 and/or EC No. 1935/2004, EU 10/2011. Like other filter types, they are also available in an antistatic design.

In many cases filter materials with high-performance ePTFE membrane are used.

There are also special versions available which are made completely of special stainless steel fabric laminates.

For every cartridge type we place the highest value on perfect manufacturing and an optimum in process performance.

Filters for air processing and dedusting systems

Filters for air processing and dedusting systems

Looking for a reliable partner who will take care of all your process filters?

We can supply you with all the necessary filters of European manufacturers for your AHUs (Air Handling Units) which treat the incoming air for your processing systems:

- pre-filter cells

- pocket filters

- compact filters

- HEPA filters

- high-temperature HEPA filters

Cleanable HEPA filter cassettes

Furthermore we supply high-quality HEPA filter cassettes for cleanable HEPA filter units. These are manufactured from a special PTFE-coated filter medium and supplied with certificate (leak and earthing test).

Filters for dedusting equipment

We also supply you with all the necessary filter elements for all police filters (dedusting equipment) behind your pharmaceutical processing machinery, such as fluidized bed systems or tablet coaters.

- multi-filter pockets

- star filters

- filter cartridges, pleated

- filter panels, pleated

- filter panels made of sintered polyethylene with PTFE

Particulate monitoring technology for fluidized bed systems

Particulate monitoring technology for fluidized bed systems

Product loss, for example due to a damaged filter, can quickly reduce the production gain.

With the help of available monitoring technology which immediately detects a filter break, you can reliably protect yourself against product loss and reduce cleaning work of dirty pipes caused by damaged filter.

The particulate monitoring technology was developed especially to reliably measure the dust content in clean gas downstream of the fluidized bed equipment.

The generated 4…20 mA signal can be integrated in the controls of the fluidized bed system, so it can immediately stop the fluidized bed process if a filter break occurs.

The particulate monitoring technology operates based on the triboelectric effect. In contrast with other dust detectors, dust accumulation on the sensor antenna is non-critical and does not lead to falsified measurements or even malfunctions.

It is suitable for use starting at particle sizes of 0.3 μm and larger. Emissions in a range of 0.1 mg/m³ to 1000 g/m³ can be measured.

With their robust design, our sensors are designed for many years of constant reliable use with low maintenance requirements.

The WOKU Group is a group of companies with multiple locations which has been in operation since 1979 and specialises in the manufacture of textile filter elements, supplying these products to customers around the world. The main plant with production facilities can be found in Beckum (Germany). Three other production sites can be found in Goethestadt Bad Lauchstädt (Germany), Kaunas (Lithuania) and Zory (Poland).